GWC 4CR - Technological Studies (2011/12)

Monday, 20 February 2012

Friday, 13 January 2012

Electronics Today

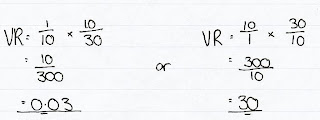

Today we reminded ourselves of voltage dividers. Here are the examples I did to help work out unknown resistances:

Thursday, 8 December 2011

Systems and Control - Mini Test - Outcome 1 and 2

Here are the questions we looked at today in the mini test:

a) Closed loop control (continuous)

b) Negative Feedback

c) Error detector - to compare the actual temperature to the set temperature and send a signal to the control. i.e. if the temperature is higher than the set level then a negative signal will be sent to the control, if the temperature is lower than the set level then a positive signal will be sent.

d) The desired temperature is set by the user. The error detector then compares this set level to the actual temperature in the oven, sensed by the temperature sensor. If it is too cold the error detector will send a positive signal to the control which will turn on the oven to heat up. When it reaches the correct temperature there will be no difference between the set temperature and the sensed temperature and so the error detector will send a 0 signal to the control which will switch off the oven. If it is too hot then the sensed temperature will be higher than the set temperature and the error detector will send a negative signal to the control which will keep the oven off. This system of constantly monitoring the temperature will mean that the oven will maintain a constant temperature.

e) Thermistor

a) Open Loop Control

b)

a) Sequential Control - A series of events happen one after the other. The end of one event signals for the start of the next. So the green traffic light switching off will send the signal to switch on the amber light.

b) Continuous Control - This is a system where the input (temperature sensor) is sending information into the system all the time and the outputs (heater) are being controlled all of the time. A change in the input directly results in a change in the output. In this example if it is sensed to be too hot, the heater will turn down, if it is sensed to be too cold the heater will be turned up, maintaining a constant temperature.

c) On/Off Control - The system can only ever be in one state: on or off, and nothing in between. This is the type of control used in the conveyor belt. It will keep moving until a box is sensed and then the motor will switch off, stopping the belt.

a) Closed loop control (continuous)

b) Negative Feedback

c) Error detector - to compare the actual temperature to the set temperature and send a signal to the control. i.e. if the temperature is higher than the set level then a negative signal will be sent to the control, if the temperature is lower than the set level then a positive signal will be sent.

d) The desired temperature is set by the user. The error detector then compares this set level to the actual temperature in the oven, sensed by the temperature sensor. If it is too cold the error detector will send a positive signal to the control which will turn on the oven to heat up. When it reaches the correct temperature there will be no difference between the set temperature and the sensed temperature and so the error detector will send a 0 signal to the control which will switch off the oven. If it is too hot then the sensed temperature will be higher than the set temperature and the error detector will send a negative signal to the control which will keep the oven off. This system of constantly monitoring the temperature will mean that the oven will maintain a constant temperature.

e) Thermistor

a) Open Loop Control

b)

a) Sequential Control - A series of events happen one after the other. The end of one event signals for the start of the next. So the green traffic light switching off will send the signal to switch on the amber light.

b) Continuous Control - This is a system where the input (temperature sensor) is sending information into the system all the time and the outputs (heater) are being controlled all of the time. A change in the input directly results in a change in the output. In this example if it is sensed to be too hot, the heater will turn down, if it is sensed to be too cold the heater will be turned up, maintaining a constant temperature.

c) On/Off Control - The system can only ever be in one state: on or off, and nothing in between. This is the type of control used in the conveyor belt. It will keep moving until a box is sensed and then the motor will switch off, stopping the belt.

Tuesday, 15 November 2011

Systems and Control

Here is a quick break down of how to draw System Diagrams from last year as a reminder.

We will be looking at systems which use Microprocessors, but you could have electronic components or mechanical systems as your process as well.

Now we need to know about control diagrams as well. These are similar in many ways to system diagrams, but they include an error detector as part of the control.

Control diagrams are mainly used to describe systems which have closed loop control. That is that they self regulate the output. This means that they need to include some sort of sensor to monitor what the output is doing. Open loop control systems have no ability to control the output any better than switching it on or off. This can be seen in the lights in the classroom. They do not dim when it is bright outside, they are switched on, and they stay on at the same brightness until they are switched off. An oven, on the other hand uses closed loop control. You set the temperature and it heats up until it is at that temperature, then the temperature in the oven is closely monitored and the heating element switched on and off to keep it as close to the set temperature as possible.

The error detector compares the sensed, actual value and the set/desired level and gives a signal accordingly. Normally this signal would go either to the process, or to the control unit, depending on the level of detail required. The diagram below shows only the process.

The diagram above shows a closed loop system using negative feedback. This means that it works to try to reduce the difference between the set/desired level and the actual level sensed by the output sensor - the error. As shown above, if the actual temperature is too cold, the error detector will give a high signal, switching the heater on; if the temperature is too hot, the error detector will give a low signal and the heater will turn off.

This can also be shown in this graph:

You can see clearly that the system is trying to stay at the desired temperature, but the deign of the system means that as soon as it is too hot, the heater is switched off, but this takes some time to cool down. When it is too cold it takes some time to warm up again. The space on the graph that is above and below the desired temperature shows the error - the difference. Negative feedback works to reduce this error.

Positive feedback is not often used. It amplifies the error between what you want and what the sensed output is. And so the error gets bigger and bigger. This can be heard when you stand too close to the amp with an electric guitar and you get a giant squeal out of it!

There are three types of closed loop control you need to know about:

On/Off Control: The system can only ever be in one state: on or off, and nothing in between. This is the type of control used in the oven. It is constantly switching on and off to try to keep the temperature to the desired level.

Continuous Control: This is a system where the inputs (often sensors) are sending information into the system all the time and the outputs are being controlled all of the time. A change in the input directly results in a change in the output. This is the type of control used in a robotic arm - a signal to tell the system where the desired position is given, this is compared to the signal from the arm sensor feeding back the actual position of the arm. As the arm moves this position is fed back to the control until it is in the correct position and the arm stops moving.

Sequential Control: A series of events happen one after the other. The end of one event signals for the start of the next. This is the type of control used in a washing machine as it goes through the wash cycle.

We will be looking at systems which use Microprocessors, but you could have electronic components or mechanical systems as your process as well.

Now we need to know about control diagrams as well. These are similar in many ways to system diagrams, but they include an error detector as part of the control.

Control diagrams are mainly used to describe systems which have closed loop control. That is that they self regulate the output. This means that they need to include some sort of sensor to monitor what the output is doing. Open loop control systems have no ability to control the output any better than switching it on or off. This can be seen in the lights in the classroom. They do not dim when it is bright outside, they are switched on, and they stay on at the same brightness until they are switched off. An oven, on the other hand uses closed loop control. You set the temperature and it heats up until it is at that temperature, then the temperature in the oven is closely monitored and the heating element switched on and off to keep it as close to the set temperature as possible.

The error detector compares the sensed, actual value and the set/desired level and gives a signal accordingly. Normally this signal would go either to the process, or to the control unit, depending on the level of detail required. The diagram below shows only the process.

The diagram above shows a closed loop system using negative feedback. This means that it works to try to reduce the difference between the set/desired level and the actual level sensed by the output sensor - the error. As shown above, if the actual temperature is too cold, the error detector will give a high signal, switching the heater on; if the temperature is too hot, the error detector will give a low signal and the heater will turn off.

This can also be shown in this graph:

You can see clearly that the system is trying to stay at the desired temperature, but the deign of the system means that as soon as it is too hot, the heater is switched off, but this takes some time to cool down. When it is too cold it takes some time to warm up again. The space on the graph that is above and below the desired temperature shows the error - the difference. Negative feedback works to reduce this error.

Positive feedback is not often used. It amplifies the error between what you want and what the sensed output is. And so the error gets bigger and bigger. This can be heard when you stand too close to the amp with an electric guitar and you get a giant squeal out of it!

There are three types of closed loop control you need to know about:

On/Off Control: The system can only ever be in one state: on or off, and nothing in between. This is the type of control used in the oven. It is constantly switching on and off to try to keep the temperature to the desired level.

Continuous Control: This is a system where the inputs (often sensors) are sending information into the system all the time and the outputs are being controlled all of the time. A change in the input directly results in a change in the output. This is the type of control used in a robotic arm - a signal to tell the system where the desired position is given, this is compared to the signal from the arm sensor feeding back the actual position of the arm. As the arm moves this position is fed back to the control until it is in the correct position and the arm stops moving.

Sequential Control: A series of events happen one after the other. The end of one event signals for the start of the next. This is the type of control used in a washing machine as it goes through the wash cycle.

Monday, 7 November 2011

Today's Pneumatic Revision

1. Draw an air bleed circuit which would outstroke a single acting cylinder.

2. Show how a 5/2 valve can control a double acting cylinder. The signals to actuate the 5/2 valve should come from two 3/2 push button spring return valves.

3. Draw a circuit which will outstroke a single acting cylinder if a microswitch is pressed or a push button on a 3/2 valve is pressed

4/ Calculate the outstroke and instroke force of a cylinder of diameter 50mm and a rod diameter of 3mm. The air pressure is 0.3 N/mm2

2. Show how a 5/2 valve can control a double acting cylinder. The signals to actuate the 5/2 valve should come from two 3/2 push button spring return valves.

3. Draw a circuit which will outstroke a single acting cylinder if a microswitch is pressed or a push button on a 3/2 valve is pressed

4/ Calculate the outstroke and instroke force of a cylinder of diameter 50mm and a rod diameter of 3mm. The air pressure is 0.3 N/mm2

Monday, 31 October 2011

Some More Pneumatics Revision

Today I set some dates so you know what is coming up homework-wise and NAB-wise. They are:

14/11/11 - Mechanisms and Pneumatics NAB

Today we looked at this circuit and answered the questions below. Again I will leave the answers as a comment so that you can attempt the questions again first before reading.

3/11/11 - Practice NAB in class to include both mechanisms and Pneumatics

7/11/11 - Pneumatics Homework to be handed in

(this is in the back of your booklet and should be answered on lined paper)

- Also if you got less than 31 marks in the Mechanisms homework you need to resubmit this also

(remember to come in on Wednesday lunchtime for some extra help)

Today we looked at this circuit and answered the questions below. Again I will leave the answers as a comment so that you can attempt the questions again first before reading.

Thursday, 27 October 2011

Today's Pneumatic Revision

Today we looked at the following pneumatic circuit to check our understanding of pneumatics:

1. Give the full name of all the valves/components.

2. What function do the three highlighted sub-systems perform?

3. Describe the operation of the circuit.

4. If the double acting cylinder has a diameter of 30mm and a rod diameter of 5mm; and the supplied air pressure is 5N/mm, calculate:

a) The outstroke force

b) The instroke force

I will leave the answers as a comment so you can have a chance to answer the above questions before seeing them.

1. Give the full name of all the valves/components.

2. What function do the three highlighted sub-systems perform?

3. Describe the operation of the circuit.

4. If the double acting cylinder has a diameter of 30mm and a rod diameter of 5mm; and the supplied air pressure is 5N/mm, calculate:

a) The outstroke force

b) The instroke force

I will leave the answers as a comment so you can have a chance to answer the above questions before seeing them.

Wednesday, 26 October 2011

Pneumatics

In this topic you need to be able to identify and describe pneumatic circuits and also, as for the NAB, draw these circuits from scratch.

It is therefore very important that you understand how to draw the symbols that you will need to use.

Cylinders:

You can see that the single acting cylinder has one input port which, when air flows in, will outstroke the cylinder. The spring will make the cylinder instroke as soon as this input air stops.

The double acting cylinder has two input ports, one at each end. This means that air operates the cylinder for both instroke and outstroke.

Valve Symbols:

The symbols for valves show where external connections (i.e. for main air or exhaust) are connected, as well as the internal connections for each state.

3/2 Valves:

3/2 valves are so called because they have 3 ports and two different states. The symbol for a 3/2 valve is in two parts to show the two different states it can be in. The bottom box typically shows the state a valve would be in when just out of the box, or unactuated. This means that main air is not flowing into the valve, and any excess air in the system can escape out of the exhaust:

The top box is the "action" box. This is when actuated the valve will allow main air to flow through the valve:

(note, that although I have added main air and exhaust here to help explain, all connections should be drawn on the bottom box.)

To finish your symbol you need to add the actuators. The actuator make the box they are attached to "happen". So in this case the push button actuates the valve and allows main air to flow from port 1 to 2. The spring pushes the top back up again to block off main air when the button is released.

5/2 Valves:

5/2 valves are so called because they have 5 ports and 2 states. They are primarily used to control a double acting cylinder as main air is always flowing through the 5/2 valve to hold the cylinder outstroke or instroke. The change of state in a 5/2 valve simply means that main air flows from port 1 > 2 or port 1 > 4, unlike the 3/2 valve which either allowed main air to flow, or blocked it off.

State 1 > 2:

State 1 > 4:

5/2, lever lever valve controlling a double acting cylinder:

Note how all connections are drawn on the left hand box.

Unidirectional Flow Control Restrictors:

A unidirectional FCR combines a bi-directional FCR and a one way valve. In the diagram below, if the air flows from right to left, it pushes the ball out of the one way valve and air can freely flow along the top of the Unidirectional FCR. If the air flows from left to right the air pushes the ball into the one way valve which blocks it off and therefore the air is forced to go through the restrictor.

When using a FCR to control the speed of a cylinder it is important to remember to restrict the EXHAUST of the cylinder (the air coming out of the cylinder) so that the cylinder has full pressure air pushing it outstroke and the motion will be smooth with full force. This is shown below so that the cylinder is being slowed down on outstroke, but will instroke full speed:

Note: just remember that the arrows for the one way valve point away from the cylinder.

Time Delay:

A reservoir can be added after an FCR to cause a time delay. The air is restricted and therefore takes some time to fill up the reservoir causing the delay. The time can be adjusted by tightening or loosening the FCR or the size of the resistors.

For more information on AND and OR control, and an excellent interactive diagram please look at the BBC Bitesize website here.

It is therefore very important that you understand how to draw the symbols that you will need to use.

Cylinders:

You can see that the single acting cylinder has one input port which, when air flows in, will outstroke the cylinder. The spring will make the cylinder instroke as soon as this input air stops.

The double acting cylinder has two input ports, one at each end. This means that air operates the cylinder for both instroke and outstroke.

Valve Symbols:

The symbols for valves show where external connections (i.e. for main air or exhaust) are connected, as well as the internal connections for each state.

3/2 Valves:

3/2 valves are so called because they have 3 ports and two different states. The symbol for a 3/2 valve is in two parts to show the two different states it can be in. The bottom box typically shows the state a valve would be in when just out of the box, or unactuated. This means that main air is not flowing into the valve, and any excess air in the system can escape out of the exhaust:

The top box is the "action" box. This is when actuated the valve will allow main air to flow through the valve:

(note, that although I have added main air and exhaust here to help explain, all connections should be drawn on the bottom box.)

To finish your symbol you need to add the actuators. The actuator make the box they are attached to "happen". So in this case the push button actuates the valve and allows main air to flow from port 1 to 2. The spring pushes the top back up again to block off main air when the button is released.

5/2 Valves:

5/2 valves are so called because they have 5 ports and 2 states. They are primarily used to control a double acting cylinder as main air is always flowing through the 5/2 valve to hold the cylinder outstroke or instroke. The change of state in a 5/2 valve simply means that main air flows from port 1 > 2 or port 1 > 4, unlike the 3/2 valve which either allowed main air to flow, or blocked it off.

State 1 > 2:

State 1 > 4:

5/2, lever lever valve controlling a double acting cylinder:

Note how all connections are drawn on the left hand box.

Unidirectional Flow Control Restrictors:

A unidirectional FCR combines a bi-directional FCR and a one way valve. In the diagram below, if the air flows from right to left, it pushes the ball out of the one way valve and air can freely flow along the top of the Unidirectional FCR. If the air flows from left to right the air pushes the ball into the one way valve which blocks it off and therefore the air is forced to go through the restrictor.

When using a FCR to control the speed of a cylinder it is important to remember to restrict the EXHAUST of the cylinder (the air coming out of the cylinder) so that the cylinder has full pressure air pushing it outstroke and the motion will be smooth with full force. This is shown below so that the cylinder is being slowed down on outstroke, but will instroke full speed:

Note: just remember that the arrows for the one way valve point away from the cylinder.

Time Delay:

A reservoir can be added after an FCR to cause a time delay. The air is restricted and therefore takes some time to fill up the reservoir causing the delay. The time can be adjusted by tightening or loosening the FCR or the size of the resistors.

For more information on AND and OR control, and an excellent interactive diagram please look at the BBC Bitesize website here.

Wednesday, 12 October 2011

Today's Mini Test

Here are the questions and answers for today's mini test:

1. Name and draw the schematic diagram for two mechanisms which transmit motion through 90.

2. Name this mechanism and state its purpose:

3. Calculate the velocity ratio of this mechanism:

4. If the motor in the above system is turning at 500 rev/min, how fast is the output turning?

5. Work out the torque of this motor:

6. Calculate the reaction forces:

7. Name and draw three types of belt which could be used in a belt and pulley system.

8. What could you add to a belt and pulley system which has stretched and become loose?

Tensioner or jockey wheel

1. Name and draw the schematic diagram for two mechanisms which transmit motion through 90.

2. Name this mechanism and state its purpose:

Ratchet and Pawl - allows movement in one direction only.

3. Calculate the velocity ratio of this mechanism:

4. If the motor in the above system is turning at 500 rev/min, how fast is the output turning?

5. Work out the torque of this motor:

6. Calculate the reaction forces:

7. Name and draw three types of belt which could be used in a belt and pulley system.

8. What could you add to a belt and pulley system which has stretched and become loose?

Tuesday, 11 October 2011

Mechanisms

Most of mechanisms was covered last year in S3. However we have learnt some new things this year:

Velocity Ratio/Linear Speed:

Like last year we had to use Velocity Ratios to work out rotational speed and we looked at how to then find the linear speed of a rope being wound around a drum.

Here are the two examples we looked at in class:

VR = 10/40 x 10/15

= 1/6 (or 0.167)

SPEEDdrum = SPEEDmotor x VR

= 500 x 1/6

= 83.3 rev/min

= 1.39 rev/sec

C = Pi x D

= 3.14 x 250

= 785mm

= 0.785m

SPEEDrope = SPEEDdrum x C

= 1.39 x 0.785

= 1.09 m/s

VR = 1/2 with 2 ropes

SPEEDload = SPEEDrope x VR

= 1.09 x 1/2

= 0.55 m/s

VR = 10/30 x 10/40

= 1/12 (or 0.083)

SPEEDdrum = SPEEDmotor x VR

= 200 x 1/12

= 16.6 rev/min

= 0.27 rev/sec

C = π x D

= 3.14 x 300

= 942mm

= 0.942m

SPEEDrope = SPEEDdrum x C

= 0.27 x 0.942

= 0.254 m/s

Moments:

A moment is the turning effect of a force. Because a force is being applied to a system, it works like a lever. So the further away from the pivot the force is applied the greater the moment. Hence you calculate a moment:

Moments work on the principle of equilibrium. This means that as the system is not actually moving, all the forces and moments are balanced. The three laws of equilibrium are:

Using these laws we can find out unknown forces or distances. These are the revision questions we looked at today:

Calculate the reaction forces in the car shown below.

First it might be useful to draw the Free Body diagram to show clearly how the forces are acting on the car. However you will notice that you are given the mass of the people in the car, not their weight, therefore to find the forces the people will exert on car, you must use W = mg:

F90 = mg F60 = mg

= 90 x 9.81 = 60 x 9.81

= 883N = 589N

Now that you know the forces, you can start to use the laws of equilibrium. Make R1 the pivot point so that you can work out R2:

Remember that a moment = force x distance from the pivot. And you must work out all moments separately, you can't add them without multiplying them by their individual distances first.

Now that we know R2, we can use the equal forces law to work out R1.

Then we looked at a car with a caravan on the back. In this question the tow bar exerts a force both on the car and on the caravan.

To tackle this question you must consider the car and the caravan separately. First look at the caravan to work out the force in the tow bar P:

So if R3 is the pivot, you can see that the person is exerting a clockwise force and P an anticlockwise one.

ΣFup = ΣFdown

Now we can work out the forces in the car. This is the free body diagram for the car:

You will notice that as P is acting up from the car. This is because there is tension in P and it is being stretched. The internal forces act to keep P from stretching. So it acts away from both the car and the caravan.

We need to use moments to find the reaction forces. I would start by making R1 the pivot, so that we can find R2:

Now we can use the equilibrium in the vertical forces equation to find R1:

ΣFup = ΣFdown

The next question is slightly easier as it only involves one system, the desk.

Again, the best place to start is by drawing the free body diagram:

Taking moments about R1, we can find R2:

Then using equilibrium in vertical forces we can find R1.

ΣFup = ΣFdown

Windlass:

A windlass uses a handle to magnify force. This can be demonstrated using the Velocity Ratio equation:

Velocity Ratio = Distance moved by effort / Distance moved by load

The distances moved are found by working out the circumference (C = 2π r). As the handle has a greater circumference you need to put in less force to lift the load when using the windlass.

Torque:

Torque is a turning force, or the turning effect of a force. This means that when a force is applied to a gear or pulley it is magnified by the distance that force is applied is from the axle, i.e. the radius. Thus, the bigger the pulley or gear, the bigger the Torque.

Therefore torque can be found using the equation:

T = Fr

Where T is Torque and is measured in Nm, F is the force, and r is radius.

Power:

Power in mechanical systems are based on P = E/t. Energy is force x distance and we base our power calculations on revolutions per second so time = 1. Because this is a turning force we need to know the torque. And the distance is the number of revolutions per second.

Hence mechanical power: P = 2πNT

P is power measured in W, N is number of turns (rev/s) and T is Torque.

Velocity Ratio/Linear Speed:

Like last year we had to use Velocity Ratios to work out rotational speed and we looked at how to then find the linear speed of a rope being wound around a drum.

Here are the two examples we looked at in class:

VR = 10/40 x 10/15

= 1/6 (or 0.167)

SPEEDdrum = SPEEDmotor x VR

= 500 x 1/6

= 83.3 rev/min

= 1.39 rev/sec

C = Pi x D

= 3.14 x 250

= 785mm

= 0.785m

SPEEDrope = SPEEDdrum x C

= 1.39 x 0.785

= 1.09 m/s

VR = 1/2 with 2 ropes

SPEEDload = SPEEDrope x VR

= 1.09 x 1/2

= 0.55 m/s

VR = 10/30 x 10/40

= 1/12 (or 0.083)

SPEEDdrum = SPEEDmotor x VR

= 200 x 1/12

= 16.6 rev/min

= 0.27 rev/sec

C = π x D

= 3.14 x 300

= 942mm

= 0.942m

SPEEDrope = SPEEDdrum x C

= 0.27 x 0.942

= 0.254 m/s

Moments:

A moment is the turning effect of a force. Because a force is being applied to a system, it works like a lever. So the further away from the pivot the force is applied the greater the moment. Hence you calculate a moment:

Moment = Force x distance

Moments work on the principle of equilibrium. This means that as the system is not actually moving, all the forces and moments are balanced. The three laws of equilibrium are:

ΣACM = ΣCWM

ΣFup = ΣFdown

ΣFleft = ΣFdown

Using these laws we can find out unknown forces or distances. These are the revision questions we looked at today:

Calculate the reaction forces in the car shown below.

First it might be useful to draw the Free Body diagram to show clearly how the forces are acting on the car. However you will notice that you are given the mass of the people in the car, not their weight, therefore to find the forces the people will exert on car, you must use W = mg:

F90 = mg F60 = mg

= 90 x 9.81 = 60 x 9.81

= 883N = 589N

Now that you know the forces, you can start to use the laws of equilibrium. Make R1 the pivot point so that you can work out R2:

Remember that a moment = force x distance from the pivot. And you must work out all moments separately, you can't add them without multiplying them by their individual distances first.

ΣACM = ΣCWM

R2 x 3.5 = (883 x 1) + (589 x 2.5)

3.5R2 = 883 + 1472.5

3.5R2 = 2355.5

R2 = 673N

ΣFup = ΣFdown

R1 + R2 = 883 + 589

R1 + 673 = 1472

R1 = 799N

Then we looked at a car with a caravan on the back. In this question the tow bar exerts a force both on the car and on the caravan.

To tackle this question you must consider the car and the caravan separately. First look at the caravan to work out the force in the tow bar P:

So if R3 is the pivot, you can see that the person is exerting a clockwise force and P an anticlockwise one.

ΣACWM = ΣCWM

P x 3.5 = 200 x 1

3.5P = 200

P = 57.1N

And using this we only have one unknown in the caravan. So we can work out R3:

ΣFup = ΣFdown

R3 = 57.1 + 200

= 257.1N

Now we can work out the forces in the car. This is the free body diagram for the car:

You will notice that as P is acting up from the car. This is because there is tension in P and it is being stretched. The internal forces act to keep P from stretching. So it acts away from both the car and the caravan.

We need to use moments to find the reaction forces. I would start by making R1 the pivot, so that we can find R2:

ΣACWM = ΣCWM

(R2 x 2.5) + (P x 5.5) = 500 x 1

2.5R2 + (57.1 x 5.5) = 500

2.5R2 + (57.1 x 5.5) = 500

2.5R2 + 314 = 500

2.5R2 = 186

2.5R2 = 186

R2 = 93N

Now we can use the equilibrium in the vertical forces equation to find R1:

ΣFup = ΣFdown

R1 + R2 = 500

R1 + 93 = 500

R1 + 93 = 500

R1 = 407N

The next question is slightly easier as it only involves one system, the desk.

Again, the best place to start is by drawing the free body diagram:

Taking moments about R1, we can find R2:

ΣACWM = ΣCWM

1 x R2 = (200 x 0.5) + (50 x 1.5)

R2 = 100 + 75

R2 = 100 + 75

R2 =175N

Then using equilibrium in vertical forces we can find R1.

ΣFup = ΣFdown

R1 + R2 = 200 + 50

R1 + 175 = 250

R1 + 175 = 250

R1 = 75N

Windlass:

A windlass uses a handle to magnify force. This can be demonstrated using the Velocity Ratio equation:

Velocity Ratio = Distance moved by effort / Distance moved by load

The distances moved are found by working out the circumference (C = 2π r). As the handle has a greater circumference you need to put in less force to lift the load when using the windlass.

Torque:

Torque is a turning force, or the turning effect of a force. This means that when a force is applied to a gear or pulley it is magnified by the distance that force is applied is from the axle, i.e. the radius. Thus, the bigger the pulley or gear, the bigger the Torque.

Therefore torque can be found using the equation:

T = Fr

Where T is Torque and is measured in Nm, F is the force, and r is radius.

Power:

Power in mechanical systems are based on P = E/t. Energy is force x distance and we base our power calculations on revolutions per second so time = 1. Because this is a turning force we need to know the torque. And the distance is the number of revolutions per second.

Hence mechanical power: P = 2πNT

P is power measured in W, N is number of turns (rev/s) and T is Torque.

Wednesday, 5 October 2011

More Energy Practice

Today in the lunchtime drop in session we looked at the transfer of energy from one type to another.

This is the example we used.

We had to find:

a) The total energy

b) The speed of the man 8m above the ground.

Answer:

a) The man at the top of the building is not moving so all of the energy he possesses is potential. This means that the total energy this man will ever have is equal to the potential energy at the top of the building as shown below.

b) At 8m above the ground the man now has some kinetic energy as he is falling and some potential energy as he is still above the ground. The total energy the man possesses hasn't changed, only the way the energy is distributed. Therefore the potential energy and the kinetic energy must add up to the total. By working out the potential energy the man has a 8m we can then work out the kinetic energy as shown below. When the kinetic energy is known, the velocity can be found, as shown below.

Other Notes:

Other things people found confusing was the input energy produced by a fuel like petrol. Fuel has an energy either per litre or per kg. Therefore the amount of fuel used must be multiplied by the energy stored in the fuel.

So if petrol has 3.5MJ of energy per kg, and uses 2kg of fuel then the total energy supplied by the fuel is 3.5MJ x 2 = 7MJ.

People also found it difficult to work out which was the input energy and which was the output energy. The only real rule in trying to work this out is to read the question carefully. It will explain in the question how the system works. It may also give you a diagram. As a rule of thumb a system diagram will read input > process > output. Therefore a diagram should be drawn in this order.

Other than the above: read the question, highlight and label all the relevant information so that it is clear what you know, and what you are aiming to find out. Use the data booklet to help you work out what equation you need to use based on what information you have.

This is the example we used.

We had to find:

a) The total energy

b) The speed of the man 8m above the ground.

Answer:

a) The man at the top of the building is not moving so all of the energy he possesses is potential. This means that the total energy this man will ever have is equal to the potential energy at the top of the building as shown below.

b) At 8m above the ground the man now has some kinetic energy as he is falling and some potential energy as he is still above the ground. The total energy the man possesses hasn't changed, only the way the energy is distributed. Therefore the potential energy and the kinetic energy must add up to the total. By working out the potential energy the man has a 8m we can then work out the kinetic energy as shown below. When the kinetic energy is known, the velocity can be found, as shown below.

Other Notes:

Other things people found confusing was the input energy produced by a fuel like petrol. Fuel has an energy either per litre or per kg. Therefore the amount of fuel used must be multiplied by the energy stored in the fuel.

So if petrol has 3.5MJ of energy per kg, and uses 2kg of fuel then the total energy supplied by the fuel is 3.5MJ x 2 = 7MJ.

People also found it difficult to work out which was the input energy and which was the output energy. The only real rule in trying to work this out is to read the question carefully. It will explain in the question how the system works. It may also give you a diagram. As a rule of thumb a system diagram will read input > process > output. Therefore a diagram should be drawn in this order.

Other than the above: read the question, highlight and label all the relevant information so that it is clear what you know, and what you are aiming to find out. Use the data booklet to help you work out what equation you need to use based on what information you have.

Subscribe to:

Posts (Atom)